Home » Control & Instrumentation

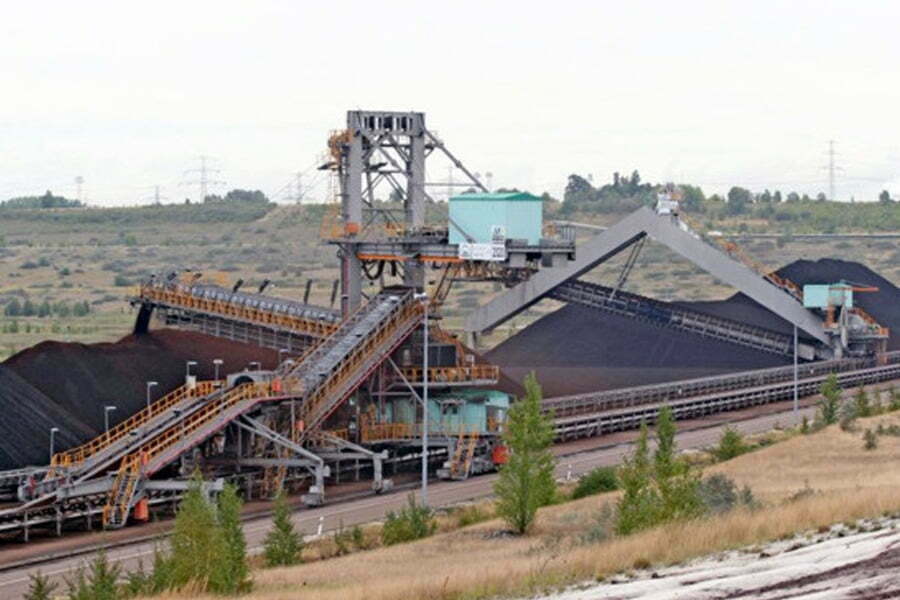

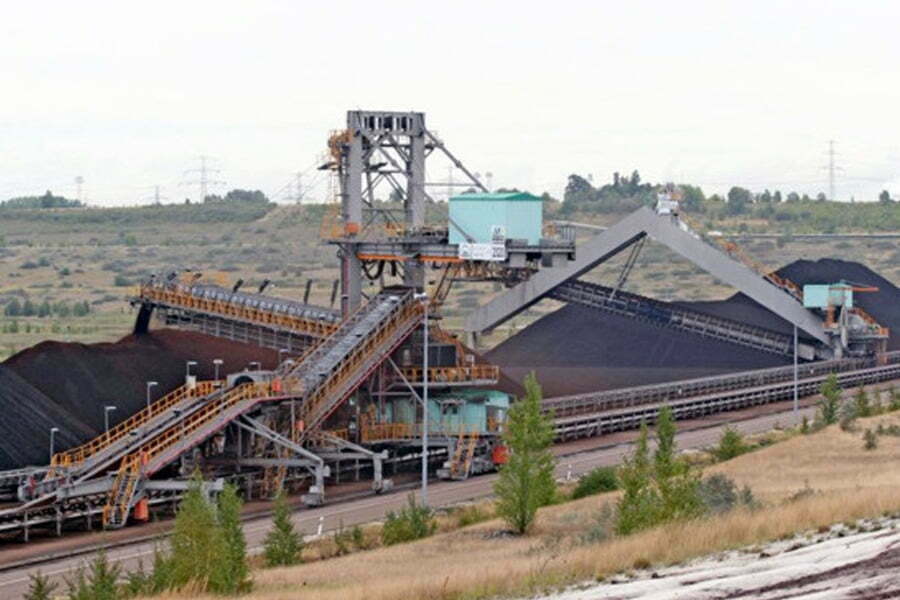

Coal handling systems are an integral part of a complete material flow and quality management system. We provide complete system optimization, including the integration of all subsystems, mine planning or advanced automation solutions that are required to deal with the increased efficiency of modern coal-fired power plants and secure the coal supply in sufficient quantity and quality. Our solution covers the Mine Site, Transportation, Stockyard and Power Plant. This is also detailing to Stockyard Management, Pile Monitoring and Visualization, Autonomous Stacking and Reclaiming, Material Tracking and Coal Quality.

Hertford design, retrofit control and electrical system for unloaders (level luffing, portal), ship loaders (combination traveling/elevated/telescopic/slewing), stacker/reclaimer, stacker, reclaimer (bucket wheel, scraper), various conveyors (air floating conveyor, flat belt conveyor, vertical conveyor), silos, and pneumatic conveying equipment for transport systems for bulk materials such as coal, flue-gas gypsum, limestone, cement, sediment, and pulp chips.

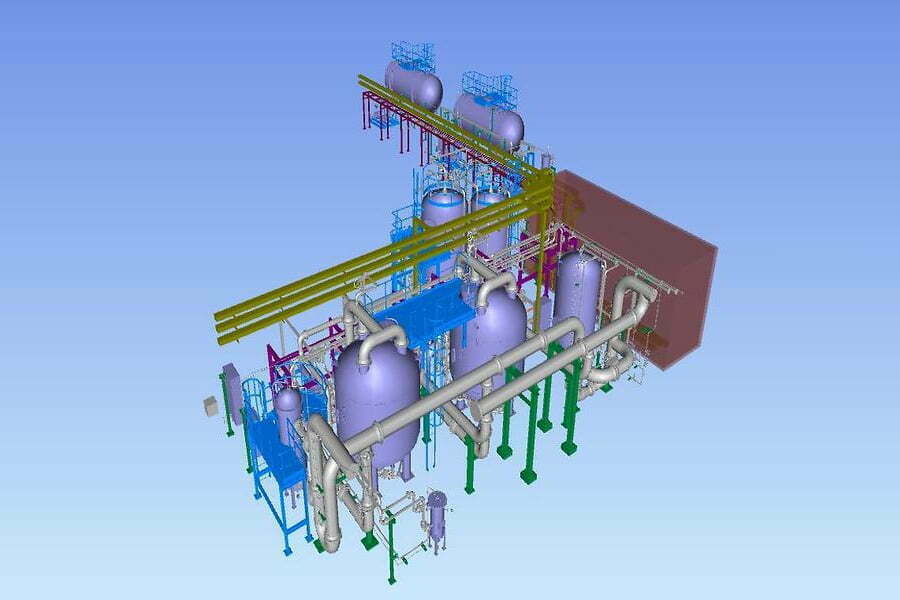

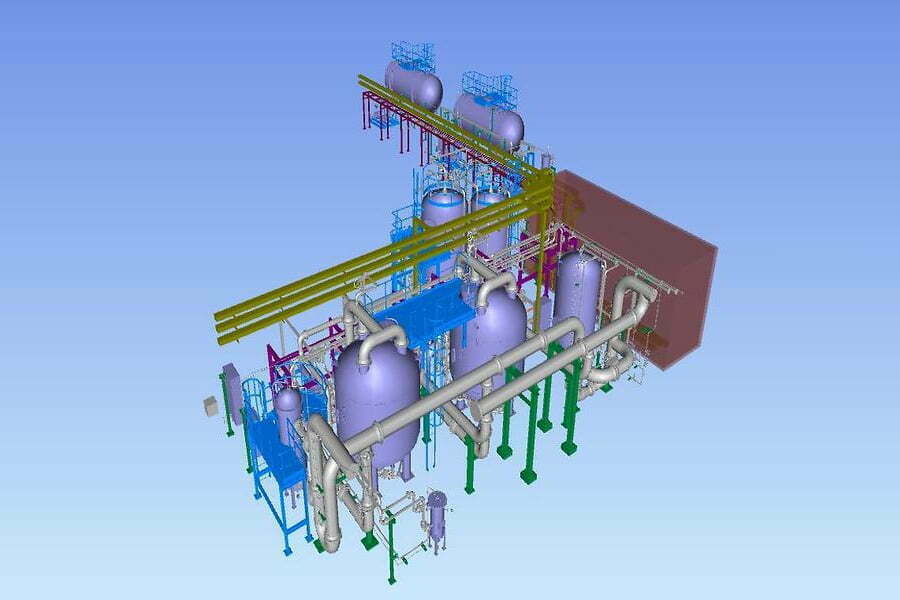

Condensate polishing is a proven method of producing high-purity water from recovered boiler condensate. The condensate can be economically returned to an ultra-pure state by simple polishing rather than using fresh make up process water. Hertford provide both hardware & software to its process control in fully-automation on all critical parameters.

Condensate polishing is a proven method of producing high-purity water from recovered boiler condensate. The condensate can be economically returned to an ultra-pure state by simple polishing rather than using fresh make up process water. Hertford provide both hardware & software to its process control in fully-automation on all critical parameters.

An electrostatic precipitator is a type of filter that uses static electricity to remove soot and ash from exhaust fumes before they exit the smokestack. Most power stations burn fossil fuels such as coal or oil to generate electricity for use. When these fuels undergo combustion, smoke produced tiny particles of soot that are suspended in hot, rising air. These unburned particles of carbon are pulled out of the smoke by using static electricity in the precipitators, leaving clean, hot air to escape the smokestacks. Our process control system provides both hardware & software handles so all critical parameters are fully automated.

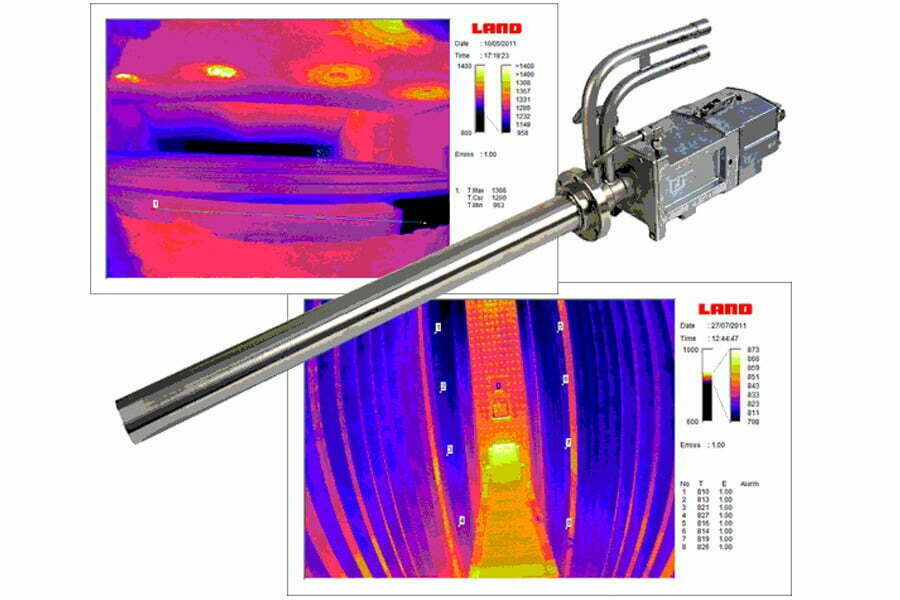

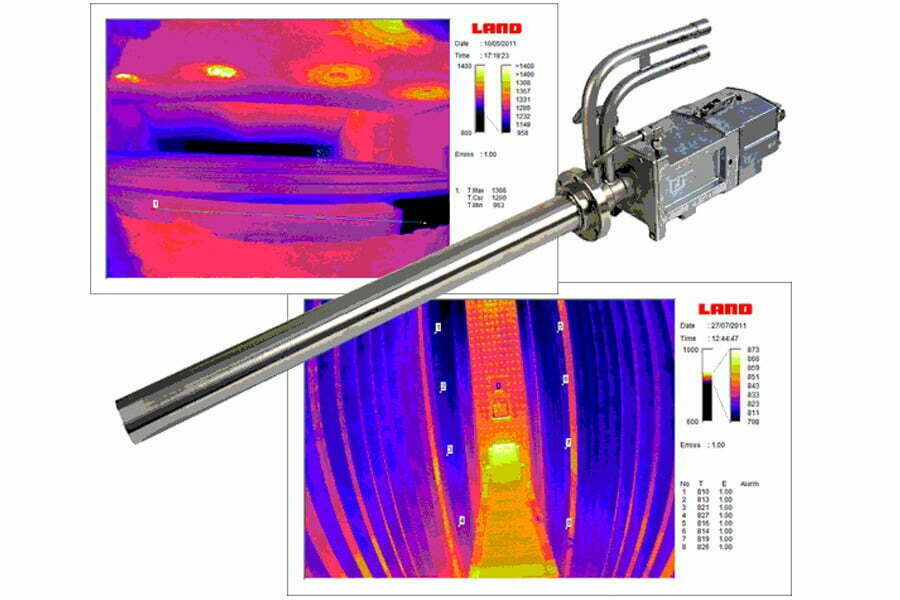

Hertford provide sales and service of high temperature and industrial process monitoring camera systems. State-of-the-art camera, thermal imaging, and temperature monitoring solutions are available for all boiler, furnace, and kiln applications. Specialized cameras and imaging systems for monitoring other process areas that are too dirty, wet or corrosive for conventional systems are also part of our extensive product line.

Continuous Hydrogen Analyzer (CHA), is built to provides petroleum refiners, petrochemical producers, and electric power generators a means to continuously and accurately monitor hydrogen concentration in gaseous streams. Utilizing a unique, patented electrochemical sensor, the CHA outputs a continuous signal corresponding directly to the hydrogen concentration. Used in conjunction with real-time controls, alarms, and shut-off mechanisms, the CHA responds immediately to changing hydrogen levels for improved operations and safety.

Dissolved Gas Analysis (DGA) and moisture measurement of the insulating oil are recognized as the most important tests for the condition assessment of transformers. Multi-gas DGA has traditionally been confined to the laboratory environment and infrequent off-line manual sampling, forming part of time based maintenance strategies. We offer discrete multigas on-line DGA and moisture monitoring for transformers. Utilizing photo-acoustic spectroscopy (PAS) measurement technology, which is well suited to field application, it provides laboratory-challenging levels of precision and repeat-ability. Full 9 gas oil sampling and analysis can be performed as often as every hour.

Hertford manufactures and supplies gas turbine temperature sensors for a variety of sectors. Gas turbine temperature sensors measure the temperature at different points in a turbine, from the exhaust temperature to the bearing temperature. In order to handle such demanding variations, exhaust gas temperature sensors must be of high quality, extremely robust and reliable. Our original temperature sensors were designed to specifically measure exhaust gasses from gas turbine engines at Wheelspace, Exhaust and Load Turner.

In temperature measurement with thermocouples, a milivoltage is generated depending on the temperature at the measuring point the reference junction temperature and the material composition of the thermocouples. Reference junction thermostats maintain the temperature of the reference junction at a constant value of 50 degree Celsius, allowing the temperature at the measuring point to be determined from the milivoltage with the aid of the standardized base value tables for thermocouples. Hertford design and build the Reference Junction Thermostats that provides accuracy for temperature measuring in the power plants.

Talk to us so that we can know you and your needs better.

Copyright © Hertford MES Sdn Bhd [201101037496 (965630-U)] Website Managed by Exabytes Malaysia. All rights reserved.